Some typical applications include chemical processing equipment, welded equipment, and more. Can be used in temperatures up to 2000☏. 321 Stainless Steelģ21 stainless steel sheet is similar to 304 stainless steel, but is somewhat easier to machine. Common applications of 316 stainless steel sheet includes heat exchangers, chemical containers, food preparation equipment, and more. This alloy has excellent forming and welding characteristics, and is durable. This alloy is commonly used in heating elements, heat exchangers, furnace parts, and more. Can be used in temperatures up to 2240☏. 309 Stainless Steelģ09 stainless steel sheet is known for good strength, oxidation resistance, and excellent heat resistance. Some common applications of 304 stainless steel sheeting include food processing equipment, heat exchangers, springs, chemical containers, and more. That’s because it’s weldable, machineable and has good corrosion resistance. This alloy is the most commonly used type of stainless steel sheet. In addition, this alloy is commonly used in small quantities for food and beverage, cryogenic, and pressure-containing applications.

302 Stainless Steelģ02 Stainless Steel is corrosion resistant, making it perfect for applications like heat exchangers, tanks, and other process equipment. 316 stainless steel encases the Petronas Towers in Malaysia, the world’s tallest buildings from 1998-2004. The pinnacle of the Chrysler Building is clad with a form of 302 stainless steel. These excellent choices for sheeting and rolling have been relied upon for some of the greatest feats of modern engineering as well as every-day applications. Luckily, the experts at All Foils have been helping partners determine the ideal types of metal alloys for their unique applications for decades.Īll Foils maintains an inventory of stainless steel alloys in the 300-grade-range including 302, 304, 309, 316, 321 and 347. There are a variety of stainless steel alloys available, and selecting one means considering a variety details such as application, density, tensile strength, workability, acid-resistance and more. Types of Stainless Steel AlloysĬhoosing the right stainless steel alloy for your application is an important step.

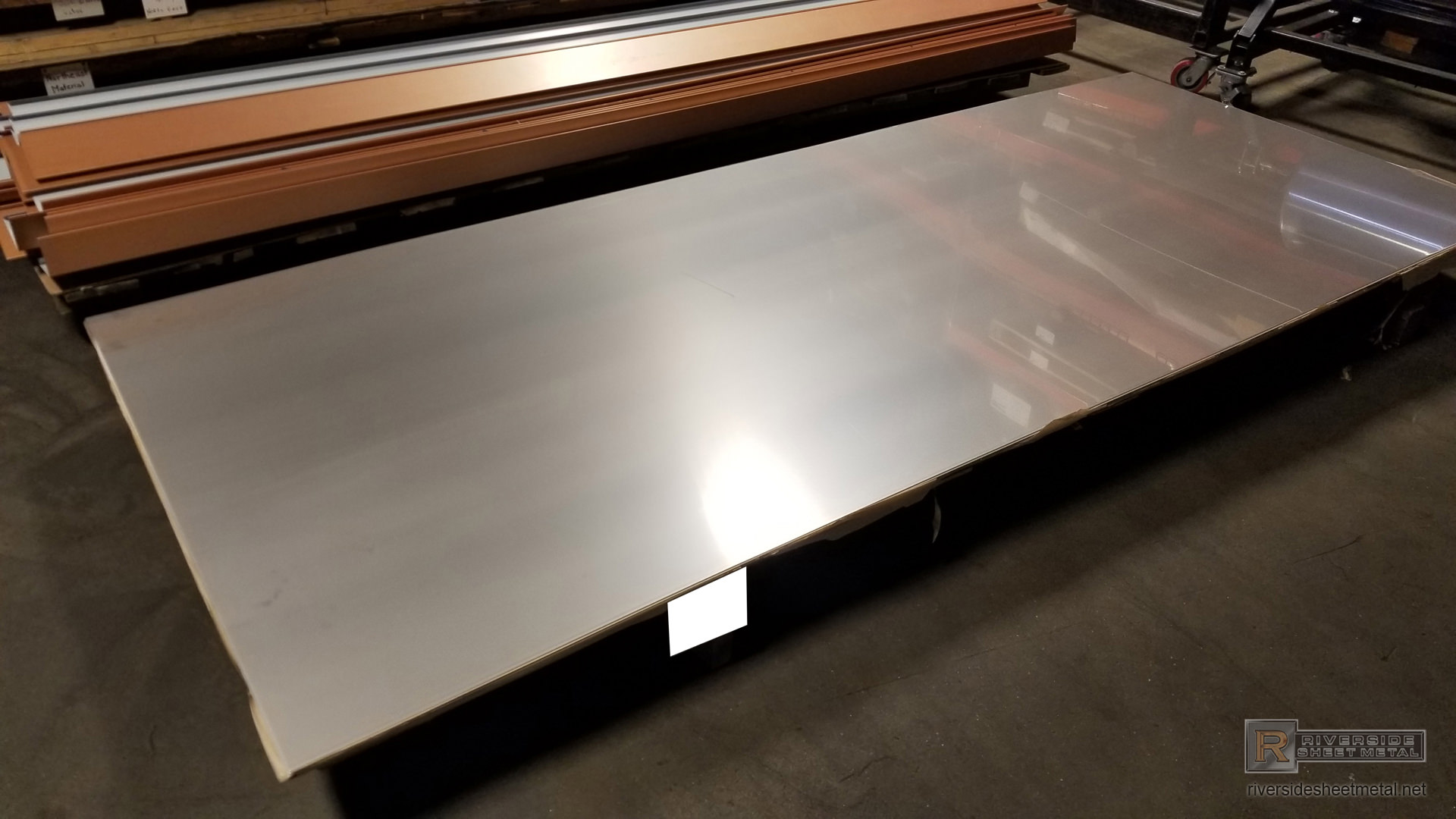

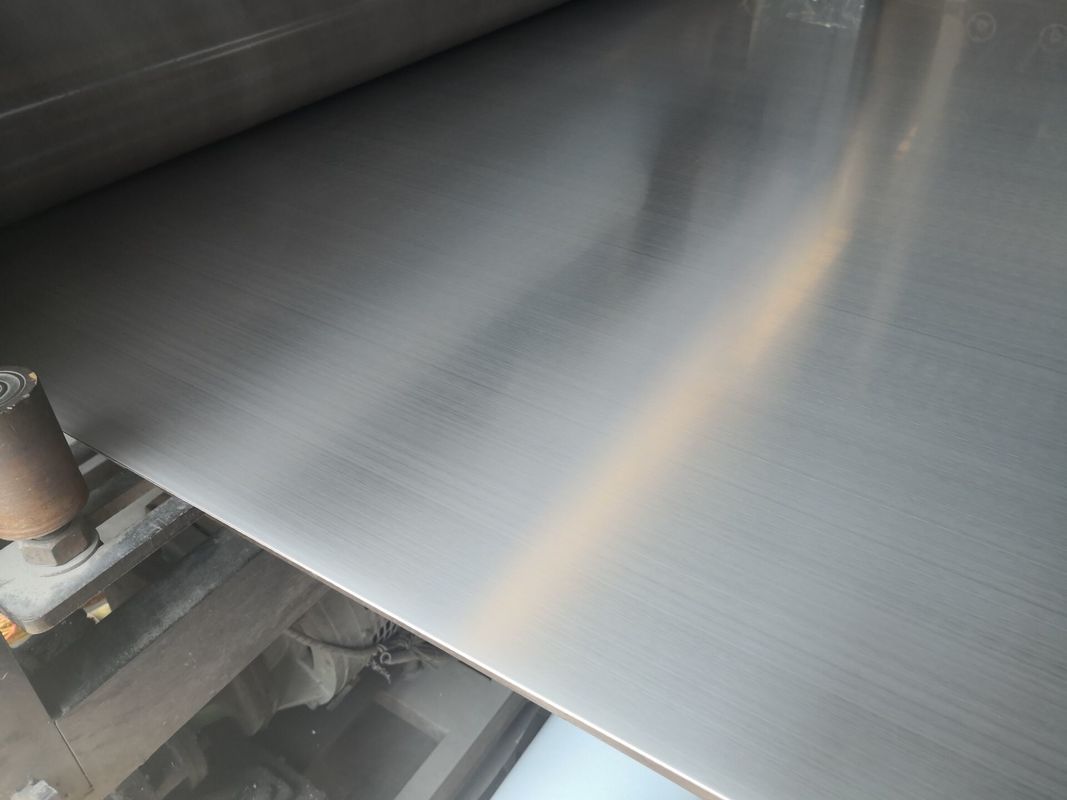

Learn more about All Foils assortment of stainless steel foil, sheeting and tape. In this case, they undergo further elevated temperature processing in order to increase their strength. However, other fabrications of stainless steel sheet, like stainless steel foil tape, require more processing. The coils can be heat treated in a furnace to further soften the material for cold rolling or to produce the mechanical properties desired.įor some stainless steel sheet products cold rolling is the last step in the process. Stainless steel coils can then be cold rolled in cold rolling mills. Thickness is gradually reduced through this process and the stainless steel product is wound into a coil at the end of the production line or cut into plates. Stainless steel sheet is produced by rolling the material through a mill, creating a thinner and longer outcome. Stainless steel sheet is typically manufactured in roll or plate form depending on thickness, or gauge. This oxide film provides the stainless-ness of stainless steel. Stainless steels are iron-based alloys containing at least 10.5% chromium which forms a protective oxide film for corrosion resistance.

0 kommentar(er)

0 kommentar(er)